BOP Parts

-

21 1/4”-2000PSI Annular BOP–Seal Kits

PWCE has the complete production line for rubber products, including packing elements and full line of seal kits.

-

21 14″-2,000 Ram BOP (Manual Lock)–Seal Kits

PWCE has the complete production line for rubber products, including packing elements and full line of seal kits.

-

Model D ANNULAR BOP–Seal Kits

PWCE has the complete production line for rubber products, including packing elements and full line of seal kits.

-

7 1/16”- 13 5/8” SL Ram BOP Rubber Packers

• Bore Size: 7 1/16”- 13 5/8”

• Working Pressures: 3000 PSI — 15000 PSI

• Certification: API,ISO9001

• Packing Details: Wooden box

-

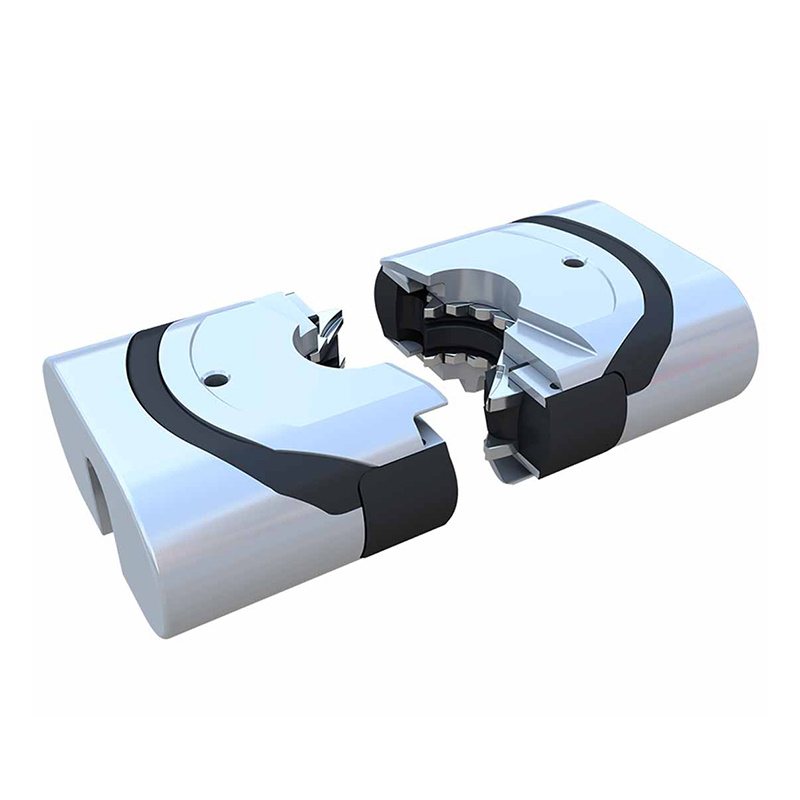

Type U VariabIe Bore Ram Assembly

·Our VBR rams are suitable for H2S service per NACE MR-01-75.

·100% interchangeable with Type U BOP

·Longer service life

·Sealing on a range of diameters

·Self-feeding elastomers

·Large reservoir of packer rubber to ensure a long-lasting seal under all conditions

·Ram packers that lock into place and are not dislodged by well-flow

-

“GK”&”GX” Type BOP packing element

-Increase service life by 30% on average

-The storage time of the packing elements can be increased to 5 years, under the shading conditions, the temperature and humidity should be controllable.

-Fully interchangeable with foreign and domestic BOP brands

- Third-party testing can be done during the production process and before leaving the factory according to customer requirements. The third-party inspection company could be BV, SGS, CSS, etc.

-

Shaffer Type Annular BOP packing element

-Increase service life by 20%-30% on average

-The storage time of the packing elements can be increased to 5 years, under the shading conditions, the temperature and humidity should be controllable.

-Fully interchangeable with foreign and domestic BOP brands

- Third-party testing can be done during the production process and before leaving the factory according to customer requirements. The third-party inspection company could be BV, SGS, CSS, etc.

-

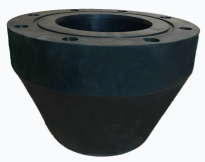

API Standard Rotary BOP Packing Element

·Improved wear resistance and longer service life.

·Better oil resistant performance.

·Optimized for overall size, easier to install on site.

-

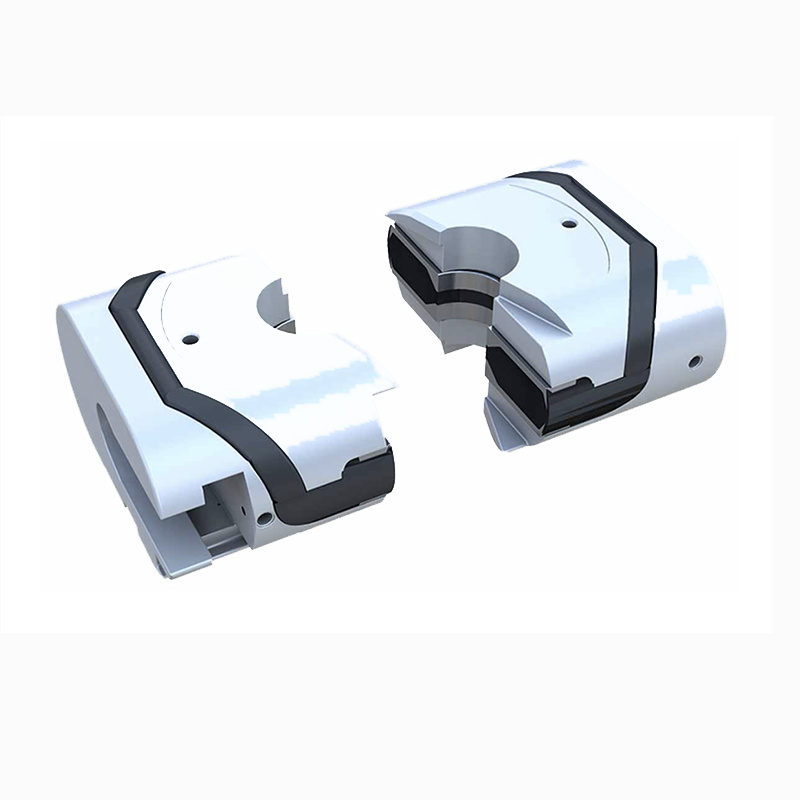

Type U Pipe Ram Assembly

·Standard: API

·Pressure: 2000~15000PSI

·Size: 7-1/16″ to 21-1/4″

· Type U, type S Available

· Shear/ Pipe/Blind/variable Rams

·Available in all common pipe sizes

·Self-feeding elastomers

·Large reservoir of packer rubber to ensure a long-lasting seal under all conditions

·Ram packers that lock into place and are not dislodged by well flow

·Suited for HPHT and H2S service

-

Shaffer Type BOP part shear ram assembly

· In accordance with API Spec.16A

· All the parts are original or interchangeable

· Reasonable structure, easy operation, long life of core

· Adapt to a wide range, capable of sealing pipe string with nominal path shapes, better performance by combining with ram blowout preventer in the use.

A shear ram can cut pipe in the well, blindly close the wellhead, and also be used as a blind ram when there is no pipe in the well. The installation of the shear ram is the same as the original ram.

-

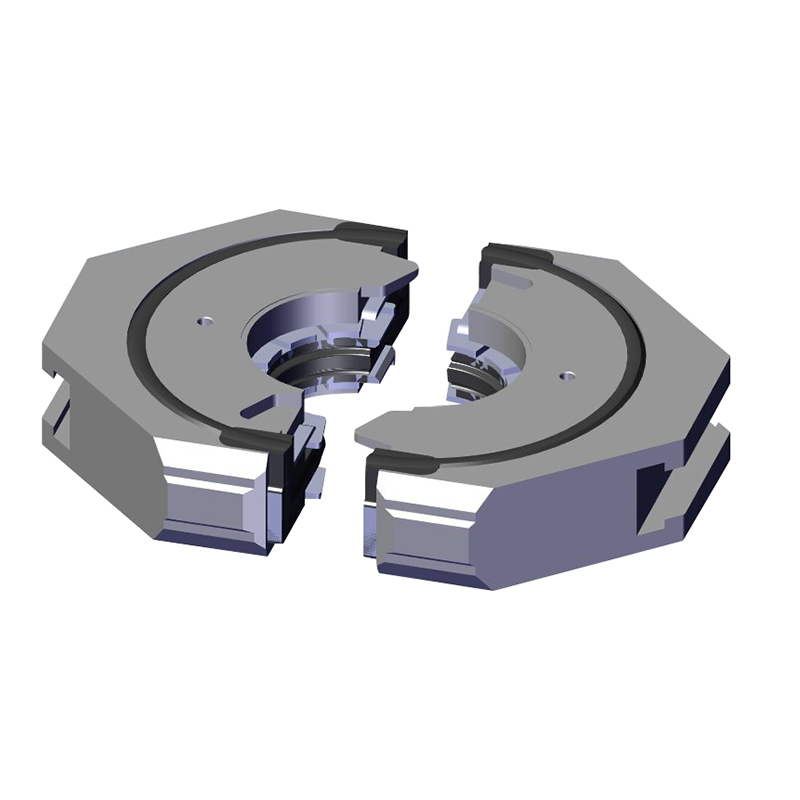

Shaffer Type Variable Bore Ram Assembly

Our VBR rams are suitable for H2S service per NACE MR-01-75.

100% interchangeable with type U BOP

Longer service life

2 7/8”-5” and 4 1/2” – 7” for 13 5/8” – 3000/5000/10000PSIBOP are available.

-

BOP part U type shear ram assembly

The large frontal area on the blade face seal reduces pressure on the rubber and increases service life.

Type U SBRs can cut pipe numerous times without damage to the cutting edge.

The single-piece body incorporates an integrated cutting edge.

H2S SBRs are available for critical service applications and include a blade material of hardened high alloy suitable for H2S service.

The type U shearing blind ram has a single-piece body with an integrated cutting edge.