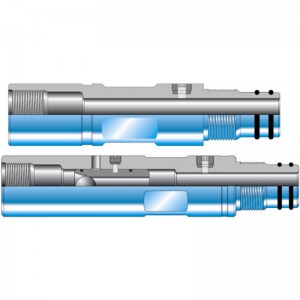

API Standard Circulation Sub

Description:

Hydraulically operated Circulation Sub offers the operator two different functions. When drilling with a mud motor, a ball may be dropped to shift the Circulation Sub into the open position, which in turn uses the drop ball to shut off the flow to the mud motor, forcing the circulation flow out of the four ports in the side of the Circulation Sub. Higher rates can be utilized once the ports are open; these rates are more than normally allowed to be put through a standard mud motor. This operation, for example, is used when milling or drilling out obstructions in a wellbore.

Upon reaching the target depth, the ball may be dropped to open the Circulation Sub and switch fluid flow over to nitrogen to unload the wellbore. With the flow to the motor shut off, the stator is not subjected to nitrogen, thus incurring no damage to the stator. The second function of the Circulation Sub comes from the integrated burst disk. These disks come in a variety of different burst pressures that can be selected by the operator for various applications.

This versatile device is essential for maintaining well integrity and efficiency. It not only facilitates the management of fluid dynamics during drilling operations but also ensures the longevity of the mud motor by preventing damage from nitrogen exposure. Moreover, its ability to switch fluid flow to nitrogen for wellbore unloading demonstrates its crucial role in well completion processes. This indispensable tool is a must-have for any drilling operation aiming for optimum performance and equipment preservation.