China Kelly Cock valve Manufacturing

Description:

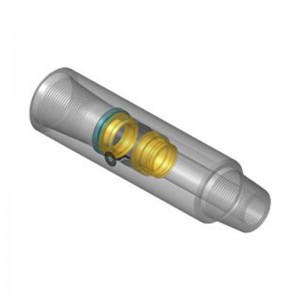

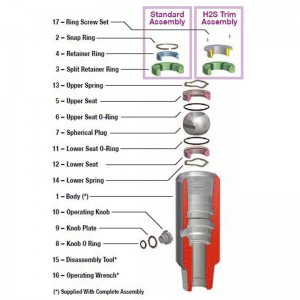

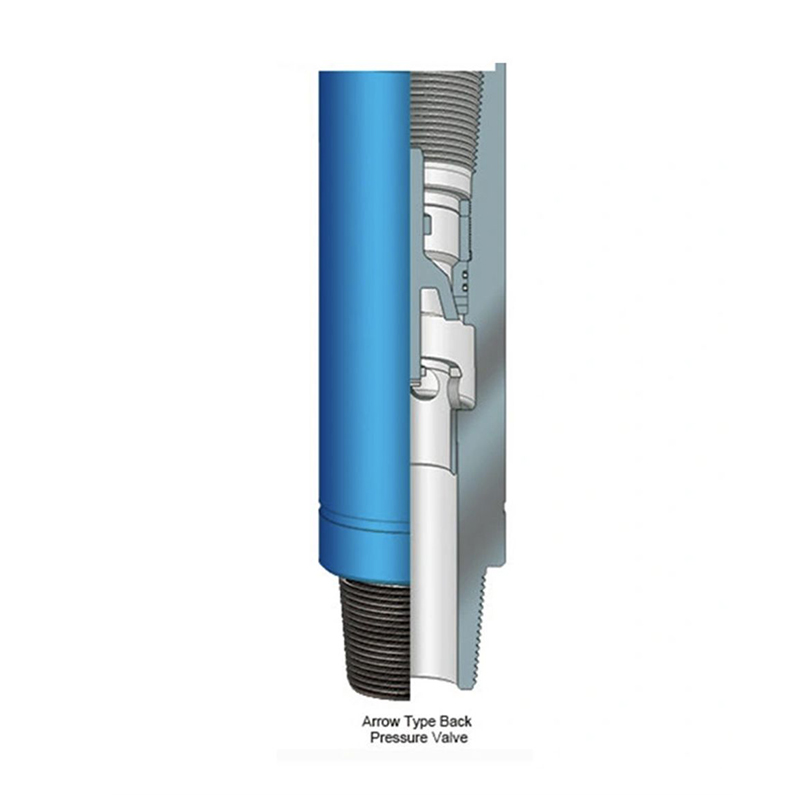

Kelly Cock Valves are devices that allow for shutting the internal bore of the drill string keeping the mud column in the top drive or the Kelly when disconnecting from the drill string. It controls the flow of the mud during normal drilling operations and is operated from the rig floor. Standard configurations include two Kelly Cock Valves; an upper Kelly Valve and a lower Kelly Valve.

Expanding on the functionality of Kelly Cock Valves, they play a pivotal role in securing the drill string and isolating wellbore pressure in the event of a kick or blowout. In addition, these valves add an extra layer of safety when tripping in and out of the hole, protecting both the rig and the crew. Our Kelly Cock Valves feature robust construction, utilizing high-grade, heat-treated alloy steel for extended longevity and optimal performance even in extreme drilling environments. They are precision-engineered to ensure reliable sealing under high-pressure conditions and are easy to operate, providing critical control in demanding situations. All these attributes make the Kelly Cock Valve an essential tool in the safe and effective management of drilling operations.

Specification

| Model | O.D. mm

(in.) |

Thread connection | I.D. mm

(in.) |

Max.sealing pressure (Mpa) |

| XS86 | 86 (3 3/8) | NC26 | 30 (1 1/16) | 35 70 105 |

| XS111 | 111 (4 3/8) | NC31 | 40 (1 37/64) | 35 70 105 |

| XS121 | 121 (4 3/4) | NC38 | 44.5 (1 3/4) | 35 70 105 |

| XS146 | 146 (5 3/4) | 4 1/2 REG LH | 44.5 (1 3/4) | 35 70 105 |

| XS168 | 168 (6 5/8) | NC50 | 71.4 (2 13/16) | 35 70 105 |

| XS178 | 178 (7) | 5 1/2 FH | 71.4 (2 13/16) | 35 70 105 |

| XS197 | 197 (7 3/4) | 6 5/8 REG LH | 76.2 (3) | 35 70 105 |