China Lifting Sub Manufacturing

Description:

The lifting sub is a special above-ground tool for lifting drilling tools in the oil and gas industry and geologic exploration. It resembles a pup joint and is used to thread the upper connection of the drill string to make the drill string be tripped in/out by the elevator. As a short type drill string component, a lifting sub looks like a completion tubing and it allows the secure and efficient handling tools that need the help of the drill pipe elevators. Complementing the robust features of our Lifting Subs, they have a design that ensures maximum strength at all points, reducing the risk of breakage or failure during the lifting process. The subs are manufactured from high-grade steel which has undergone rigorous quality testing to withstand the strenuous conditions of drilling operations. Our Lifting Subs come in various sizes and lengths to fit a range of drill string configurations. They also offer an easily accessible shoulder that enables efficient and secure latching of the elevators. These Lifting Subs provide a reliable solution for smooth, safe, and fast-tripping operations, enhancing productivity and reducing downtime in the drilling process.

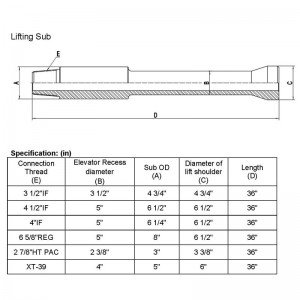

Specification

| Nominal Size mm(in) | I.D mm(in) | Coupling Thread API | Drill Pipe Outer Diameter mm(in) | Coupling Outer Diameter mm(in) |

| 73.0(2 7/8) | 31.8(1 1/4) | NC23 | 78.4(3 1/8) | 111.1(4 3/8) |

| 44.5(1 3/4) | NC26 | 88.9(3 1/2) | ||

| 88.9(3 1/2) | 54.0(2 1/8) | NC31 | 104.8(4 1/8) | 127.0(5) |

| 50.8(2) | NC35 | 120.7(4 3/4) | ||

| 68.3(2 5/8) | NC38 | 127.0(5) | ||

| 127.0(5) | 71.4(2 13/16) | NC44 | 152.4(6) | 168.3(6 5/8) |

| 71.4(2 13/16) | NC44 | 158.8(6 1/4) | ||

| 82.6(3 1/4) | NC46 | 165.1(6 1/2) | ||

| 82.6(3 1/4) | NC46 | 171.5(6 3/4) | ||

| 95.3(3 3/4) | NC50 | 177.8(7) | ||

| NC50 | 184.2(7 1/4) | |||

| NC56 | 196.8(7 3/4) | |||

| 127.0(5) | 95.3(3 3/4) | NC56 | 203.2(8) | 168.3(6 5/8) |

| 6 5/8REG | 209.6(8 1/4) | |||

| 95.3(33/4) | NC61 | 228.6(9) | ||

| 7 5/8REG | 241.3(9 1/2) | |||

| NC70 | 247.7(9 3/4) | |||

| NC70 | 254.0(10) | |||

| NC77 | 279.4(11) |