Products

-

API 6A Casing Head and Wellhead Assembly

The pressure-bearing shell is made of forged alloy steel with high strength, few defects and high pressure-bearing capacity.

The mandrel hanger is made of forgings, which leads to high bearing capacity and reliable sealing.

All metal parts of the slip hanger are made of forged alloy steel. The slip teeth are carburized and quenched. The unique tooth shape design has the characteristics of reliable operation and high bearing strength.

The valve equipped adopts a non-rising stem, which has a small switching torque and convenient operation.

The slip-type hanger and mandrel-type hanger can be interchanged.

The casing hanging mode: slip type, thread type, and sliding welding type.

-

High Pressure Wellhead H2 Choke Valve

Interchangeability of parts to construct a positive, adjustable, or combination choke.

Bonnet nut has rugged integrally forged lugs for hammering nut loose.

Built-in safety feature that releases residual pressure in the choke body before the nut is fully removed. The inside of the choke body is vented to atmosphere after the bonnet nut is partially removed.

Interchangeability of component parts for a particular pressure range. For example, the same blanking plugs and bonnet assemblies are used in nominal 2000 through 10,000 PSI WP

-

Wellhead Swing One Way Check Valve

Working Pressure:2000~20000PSI

Inside Nominal Dimension:1 13/16″~7 1/16″

Working Temperature: P-U

Product Specification Levels: PSL1~4

Performance Requirement: PR1

Material Class: AA~FF

Working Medium: oil, natural gas, etc.

-

Drum & Orifice Type Choke Valve

The body and side door are made of alloy steel.

Choke-plate design, heavy-duty, diamond-lapped tungsten-carbide plates.

Tungsten-carbide wear sleeves.

Regulate the flow quite accurately.

Versatile for onshore and offshore applications.

Long life for service.

-

API 6A Double Expanding Gate Valve

Plastic/chevron packing stays clean and free from contaminants to reduce maintenance costs.

Tight mechanical seal is assured with parallel expanding gate design.

This design provides upstream and downstream sealing simultaneously which is not affected by pressure fluctuation and vibration.

A double-row roller thrust bearing on the stem makes operation easy, even under full pressure.

-

API Certified Spacer Spool

·API 6A and NACE compliant (for H2S versions).

·Available with customized lengths and sizes

·One-piece forging

·Threaded or integral design

·Adapter spools available

·Available with quick unions

-

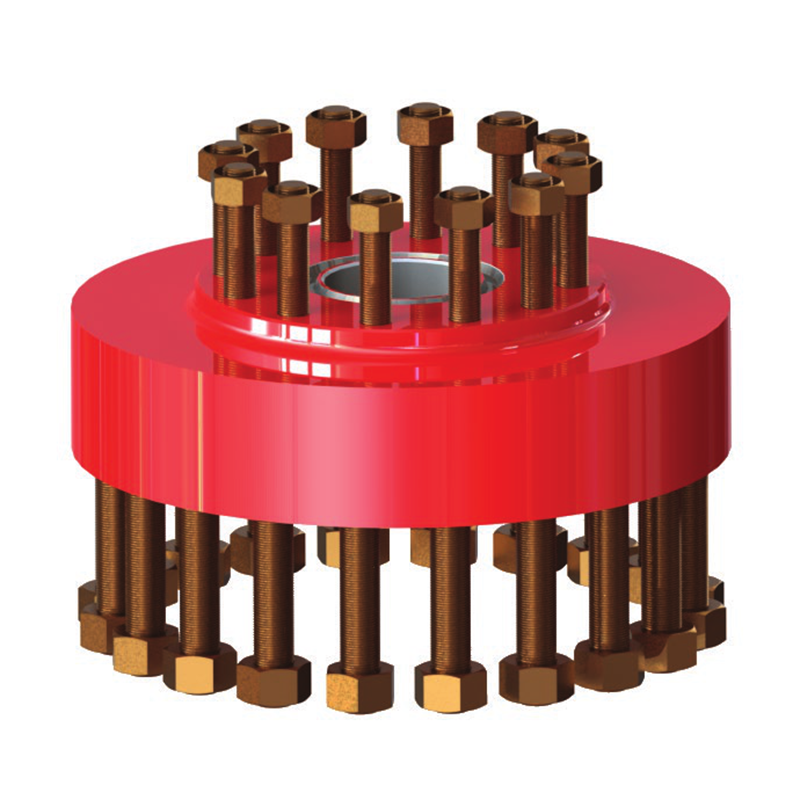

DSA – Double Studded Adapter Flange

·Can be used to connect flanges with any combination of sizes and pressure ratings

·Custom DSA’s are available to transition between API, ASME, MSS, or other styles of flanges

·Supplied with standard or customer-specific thicknesses

·Normally provided with tap-end studs and nuts

·Available for general service and sour service in compliance with any temperature rating and material requirements specified in API Specification 6A

·Available with Stainless Steel 316L or Inconel 625 corrosion-resistant ring grooves

-

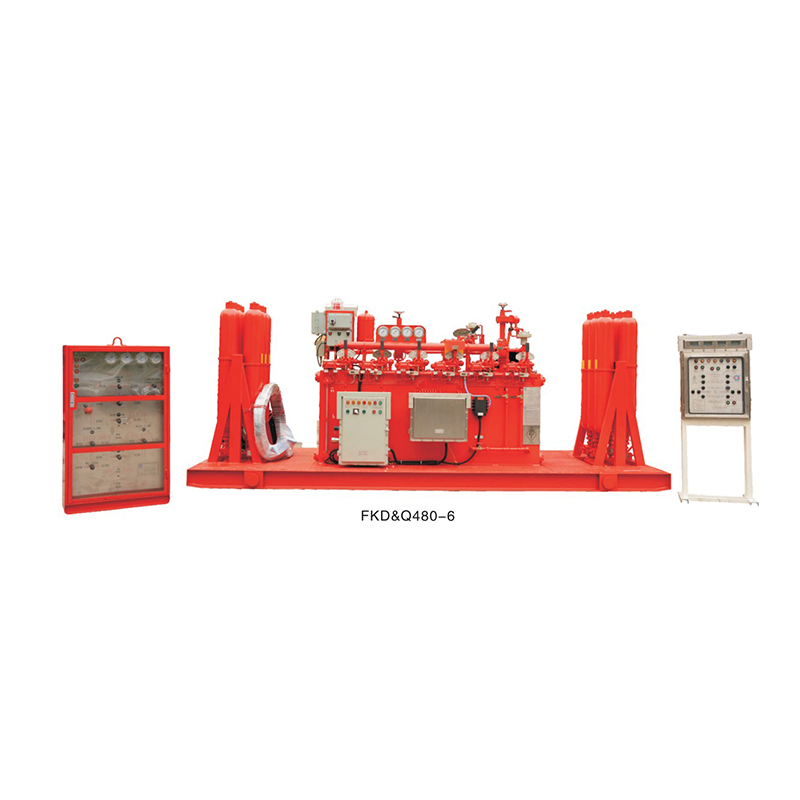

API 16D Certified BOP Closing Unit

A BOP accumulator unit (also known as a BOP closing unit) is one of the most critical components of blowout preventers. Accumulators are placed in hydraulic systems for the purpose of storing energy to be released and transferred throughout the system when it is needed to accomplish specific operations. BOP accumulator units also provide hydraulic support when pressure fluctuations occur. These fluctuations happen often in positive displacement pumps due to their operational functions of trapping and displacing fluid.

-

API 16 RCD Certified Rotary Preventer

The rotary blowout preventer is installed on top of the annular BOP. During underbalanced drilling operations and other pressure drilling operations, it serves the purpose of diverting flow by sealing the rotating drill string. When used in conjunction with drilling BOP, drill string check valves, oil-gas separators, and snubbing units, it allows for safe pressurized drilling and snubbing operations. It plays a vital role in special operations such as liberating low-pressure oil and gas layers, leak-proof drilling, air drilling, and snubbing well repairs.

-

Shaffer Type BOP part shear ram assembly

· In accordance with API Spec.16A

· All the parts are original or interchangeable

· Reasonable structure, easy operation, long life of core

· Adapt to a wide range, capable of sealing pipe string with nominal path shapes, better performance by combining with ram blowout preventer in the use.

A shear ram can cut pipe in the well, blindly close the wellhead, and also be used as a blind ram when there is no pipe in the well. The installation of the shear ram is the same as the original ram.

-

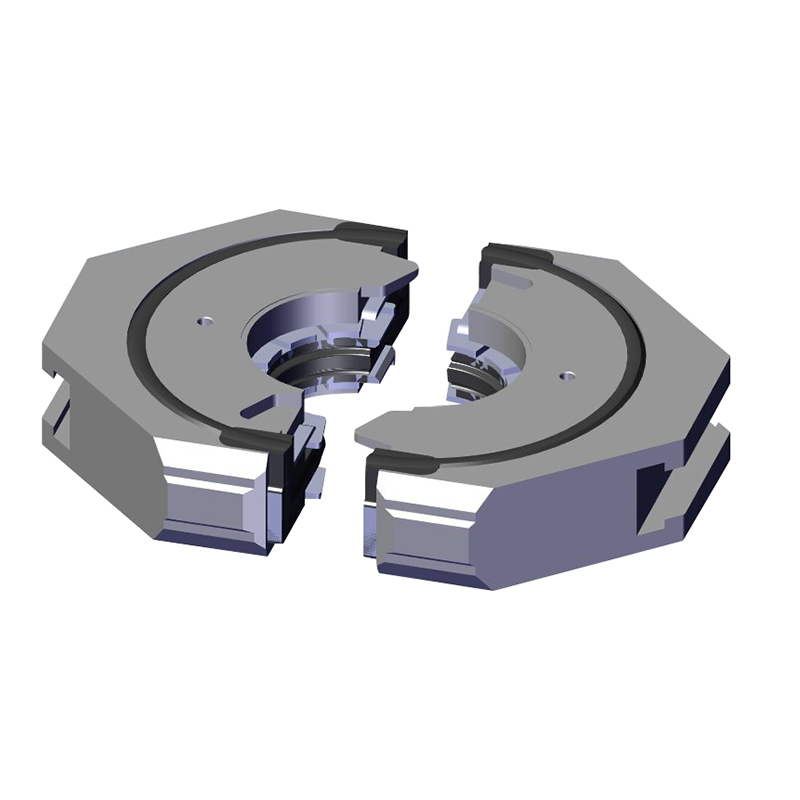

Shaffer Type Variable Bore Ram Assembly

Our VBR rams are suitable for H2S service per NACE MR-01-75.

100% interchangeable with type U BOP

Longer service life

2 7/8”-5” and 4 1/2” – 7” for 13 5/8” – 3000/5000/10000PSIBOP are available.

-

BOP part U type shear ram assembly

The large frontal area on the blade face seal reduces pressure on the rubber and increases service life.

Type U SBRs can cut pipe numerous times without damage to the cutting edge.

The single-piece body incorporates an integrated cutting edge.

H2S SBRs are available for critical service applications and include a blade material of hardened high alloy suitable for H2S service.

The type U shearing blind ram has a single-piece body with an integrated cutting edge.