Products

-

BOP Seal Kits

· Longer service life, Increase service life by 30% on average.

· Longer storage time, the storage time can be increased to 5 years, under the shading conditions, the temperature and humidity should be controllable

· Better high/low-temperature resistant performance and better sulfur-resistant performance.

-

GK GX MSP Type Annular BOP

•Application: onshore drilling rig & offshore drilling platform

•Bore Sizes: 7 1/16” — 21 1/4”

• Working Pressures: 2000 PSI — 10000 PSI

• Body Styles: Annular

• Housing Material: Casting 4130 & F22

• Packer element material: Synthetic rubber

• Third party witness and inspection report available: Bureau Veritas (BV), CCS, ABS, SGS etc.

-

Type T-81 Blowout Preventer For Well Control System

• Application: Onshore drilling rig

• Bore Sizes: 7 1/16” — 9”

• Working Pressure: 3000 PSI — 5000 PSI

• Ram style: single ram, double rams & triple rams

• Housing Material: Forging 4130

• Third-party witness and inspection report available: Bureau Veritas (BV), CCS, ABS, SGS, etc.

Manufactured in accordance with: API 16A, Fourth Edition & NACE MR0175.

• API monogrammed and suitable for H2S service as per NACE MR-0175 standard

-

Blowout Preventer Shaffer Type Lws Double Ram BOP

Application: Onshore

Bore Sizes: 7 1/16” & 11”

Working Pressures: 5000 PSI

Body Styles: Single & Double

Material: Casing 4130

Third party witness and inspection report available: Bureau Veritas (BV), CCS, ABS, SJS etc.

Manufactured in accordance with: API 16A, Fourth Edition & NACE MR0175.

API monogrammed and suitable for H2S service as per NACE MR-0175 standard

-

Diverters for well-control while drilling in the surface layer

Diverters are primarily used for well-control while drilling in the surface layer in the exploration of oil and gas. Diverters are used together with hydraulic control systems, spools and valve gates. The streams (liquid, gas) under control are transmitted to safe zones along a given route to ensure the security of well operators and equipment. It may be used to seal Kelly, drill pipes, drill pipe joints, drill collars and casings of any shape and size, at the same time it can divert or discharge the streams in well.

Diverters offer an advanced level of well control, improving safety measures while boosting drilling efficiency. These versatile devices boast a resilient design that allows for swift and effective responses to unexpected drilling challenges such as overflows or gas influxes.

-

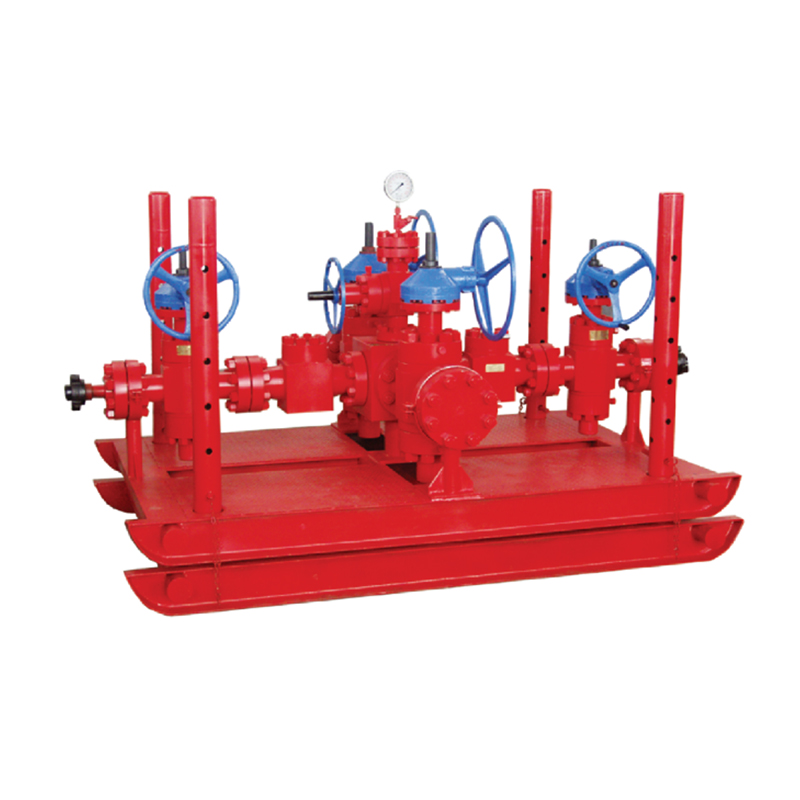

Choke Manifold and kill Manifold

·Control pressure to prevent overflow and blowout.

·Reduce wellhead casing pressure by relief function of the choke valve.

·Full-bore and two-way metal seal

·The internal of the choke is constructed with hard alloy, exhibiting a high level of resistance to erosion and corrosion.

·The relief valve helps to reduce casing pressure and protect BOP.

·Configuration type: single-wing, double-wing, multiple-wing or riser manifold

·Control type: manual, hydraulic, RTU

Kill Manifold

·Kill manifold is mainly used to kill well, prevent fire and assist in fire extinction.

-

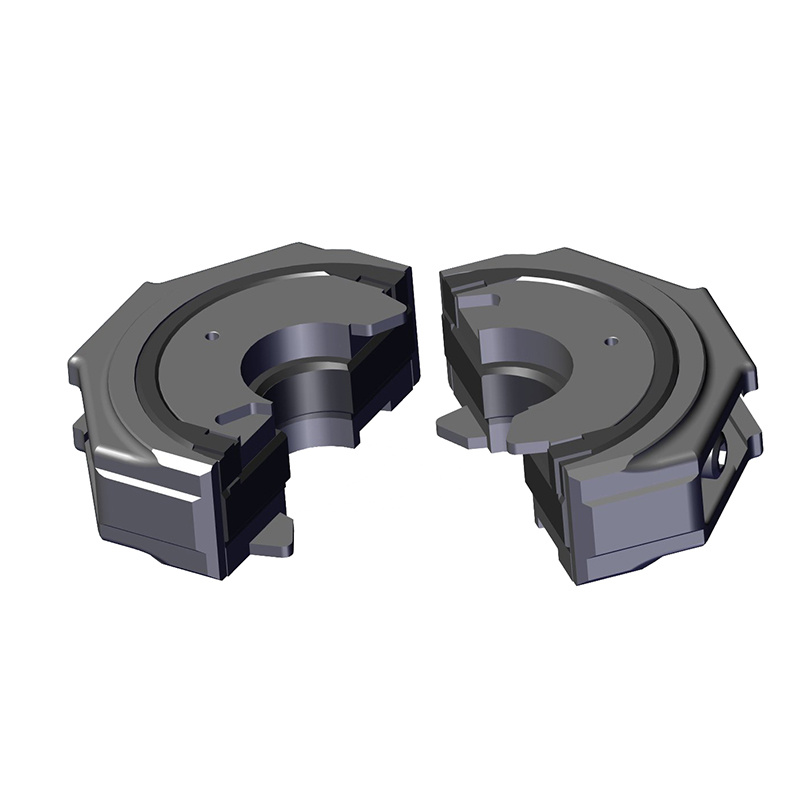

Type S Pipe Ram Assembly

The Blind Ram is used for single or double Ram Blowout Preventer(BOP). It can be closed when the well is without the pipeline or blowout.

·Standard: API

·Pressure: 2000~15000PSI

·Size: 7-1/16″ to 21-1/4″

· U type, type S Available

· Shear/ Pipe/Blind/variable Rams

-

China DM Mud Gate Valve Manufacturing

DM gate valves are commonly selected for a number of oilfield applications, including:

·MPD systems automated

·Pump-manifold block valves

·High-pressure mud mixing lines

·Standpipe manifolds

·High-pressure drilling system block valves

·Wellheads

·Well treating and frac service

·Production manifolds

·Production gathering systems

·Production flow lines

-

API 6A Manual Adjustable Choke Valve

Our Plug and Cage style choke valve features a tungsten carbide cage as the throttling mechanism with a protective steel carrier around it

Outer Steel carrier is for protection against impacts from debris in the production fluid

The trim characteristics are an equal percentage that provides superior flow control, however, we can provide the linear trim as well on-demand

Pressure-balanced trim considerably reduces the torque required to operate the choke

Plug is fully guided at the ID of the sleeve and is rigidly attached to the stem to resist any induced vibration damage

-

API Low Torque Control Plug Valve

The plug valve is mainly made up of the body, the hand wheel, the plunger and the others.

The 1502 union connection is applied to connect its inlet and outlet to the pipeline (this can be custom-made according to different requirements). the precise fit between the valve body and the liner is ensured by means of cylindrical fitting, and the sealant is inlaid through the outer cylindrical surface of the liner to make sure that it is hermetically sealed.

The cylindrical meal-to-meal fit between the liner and the plunger is adopted to ensure a high fitting accuracy and thereby reliable sealing performance.

Note: even under a pressure of 15000PSI, the valve can be opened or closed with ease.

-

Oil and gas Production Wellhead Equipment

Single Composite Tree

Used on low-pressure (up to 3000 PSI) oil wells; this type of tree is in common use worldwide. A number of joints and potential leakage points make it unsuitable for high-pressure applications or for use in gas wells. Composite dual trees are also available but are not in common use.

Single Solid Block Tree

For higher-pressure applications, the valve seats and components are installed in a one-piece solid block body. Trees of this type are available up to 10,000 PSI or even higher if required.

-

Thread Gauge for sucker rod and tubing

Our Thread Gauges for sucker rods and tubing are meticulously designed and manufactured to meet the highest industry standards. These gauges play a crucial role in ensuring the precision and compatibility of threads, contributing to the efficiency and safety of oil and gas operations. With over 25 years of expertise, our company takes pride in delivering top-notch quality control instruments that undergo rigorous testing to guarantee accuracy and durability.

Whether for routine maintenance or new installations, our Thread Gauges provide a reliable solution for assessing thread integrity and ensuring a secure fit between sucker rods and tubing components. Backed by a team of skilled professionals and state-of-the-art manufacturing facilities, we are committed to providing products that meet and exceed the expectations of our global clientele. Trust in the accuracy and reliability of our Thread Gauges for optimal performance in your oil and gas operations.