API 16 RCD Certified Rotary Preventer

Main work principle

The square drill pipe rotates in unison with the swivel stem, driven by the rotary control device's drive core assembly, thereby rotating the center tube and the rubber sealing core in the rotating sleeve. The sealing core leverages its own elastic deformation and well pressure to seal the area around the drill string. The dynamic seal between the center tube and the rotating assembly is realized by the upper and lower dynamic seal assemblies.

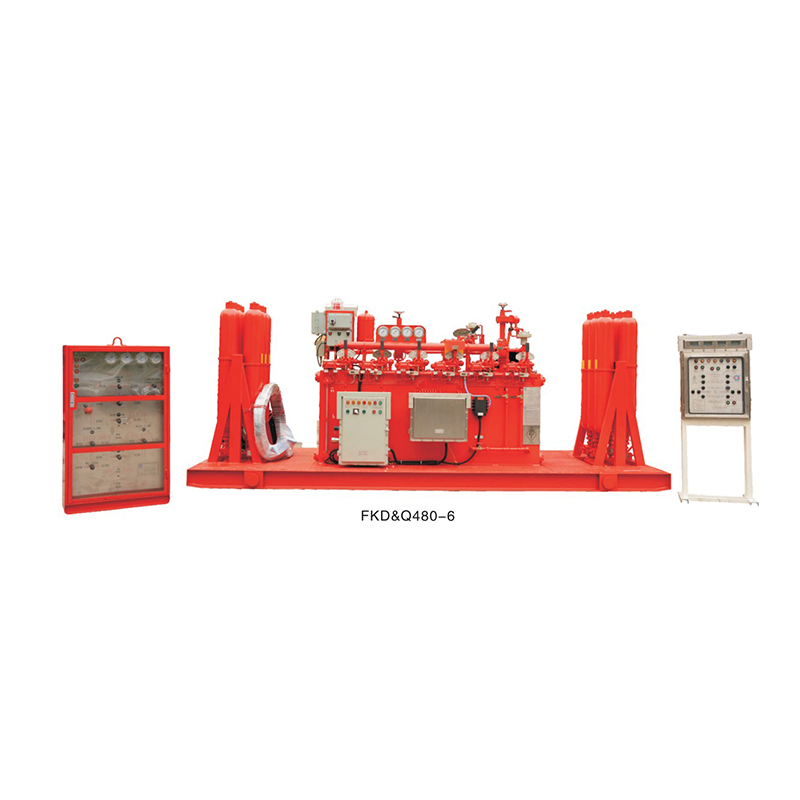

The hydraulic power station is used to control the opening and closing of the hydraulic chuck, while also providing lubricating oil for cooling the rotating assembly's internal components and the dynamic seal assembly. Cooling for the upper dynamic seal assembly is achieved through water circulation.

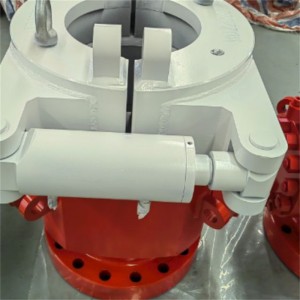

Structural Composition

The rotating blowout preventer is mainly composed of the rotating assembly, casing, hydraulic power station, control pipeline, hydraulic slab valve, and auxiliary tools.

Features

Double Rubber Core Rotating BOP

a. The double core sealing of the drill tool ensures reliable sealing and long service life.

b. On-site, it's convenient and quick to replace sealing elements or the rotating assembly without disruption from the rotating control device affecting field operations.

c. The structure is simple, easy to maintain, and has a wide range of applications.

d. The entire rotating assembly is easy to disassemble and reassemble, improving work efficiency."

Single Rubber Core Rotating BOP

a. The clamp structure is simple, and it is convenient and quick to replace the core and assembly.

b. Seal type: Passive.

c. The hydraulic device is simplified, and the operation is relatively simple.

d. The body and the lower part of the split body have a large diameter, so it is not necessary to disassemble the casing when running tools downhole.

Specification

| Model | Diameter | Static Pressure | Dynamic Pressure | Bottom Flange | Main Diameter of Overflow pipe(mm) | Operating Temperature |

| 13 5/8”-5000PSI(35-35) | 13 5/8” | 5000PSI | 2500PSI | 13 5/8”-5000PSI | ≥315 | -40~121℃ |

| 13 5/8”-10000PSI(35-70) | 13 5/8” | 5000PSI | 2500PSI | 13 5/8”-10000PSI | ≥315 | |

| 21 1/4”-2000PSI(54-14) | 21 1/4” | 2000PSI | 1000PSI | 21 1/4”-2000PSI | ≥460 | |

| 21 1/4”-5000PSI(54-35) | 21 1/4” | 5000PSI | 2500PSI | 21 1/4”-5000PSI | ≥460 |