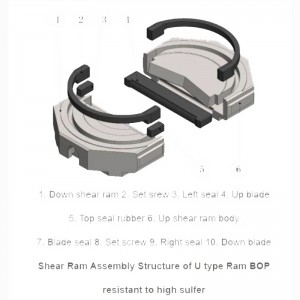

Shaffer Type BOP part shear ram assembly

Features

● In normal conditions used as a blind ram, in case of emergency, used as a shear ram.

● Shear damper can repeatedly cut pipe and not damage the blade, The worn blade can be reused after the repair.

● The ordinary ram blade is integrated with the ram body.

● The ram blade of BOP resistant to high sulfur is separated from the ram body. It is easy to change the blade after blade damaged, and makes the ram body able for repeated use.

● The contact sealing surface between the top seal of the shear ram and blade is large, which effectively reduces the pressure on the rubber sealing surface, and prolongs its life.

Description:

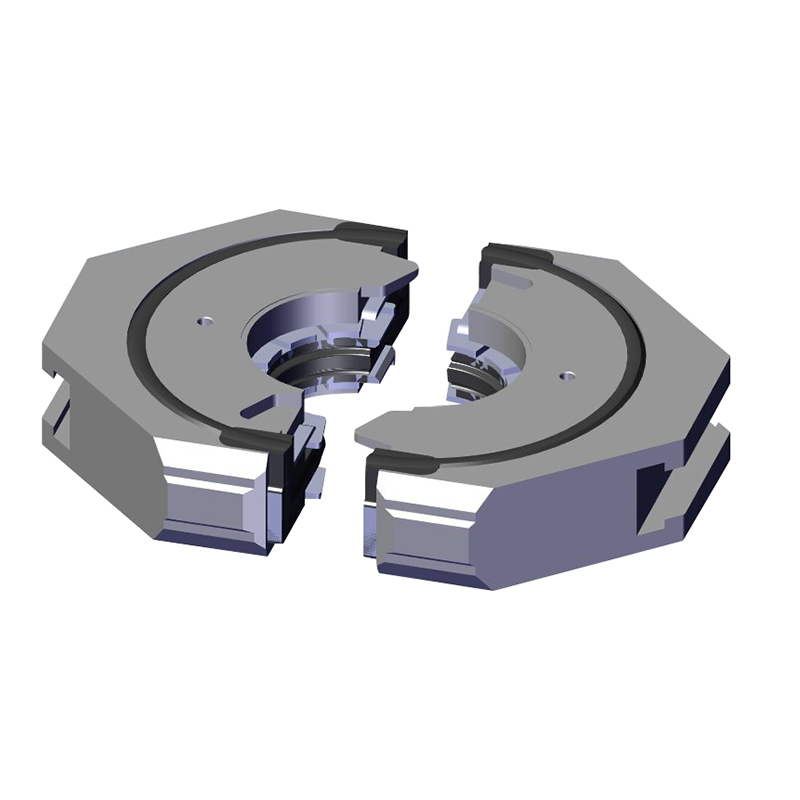

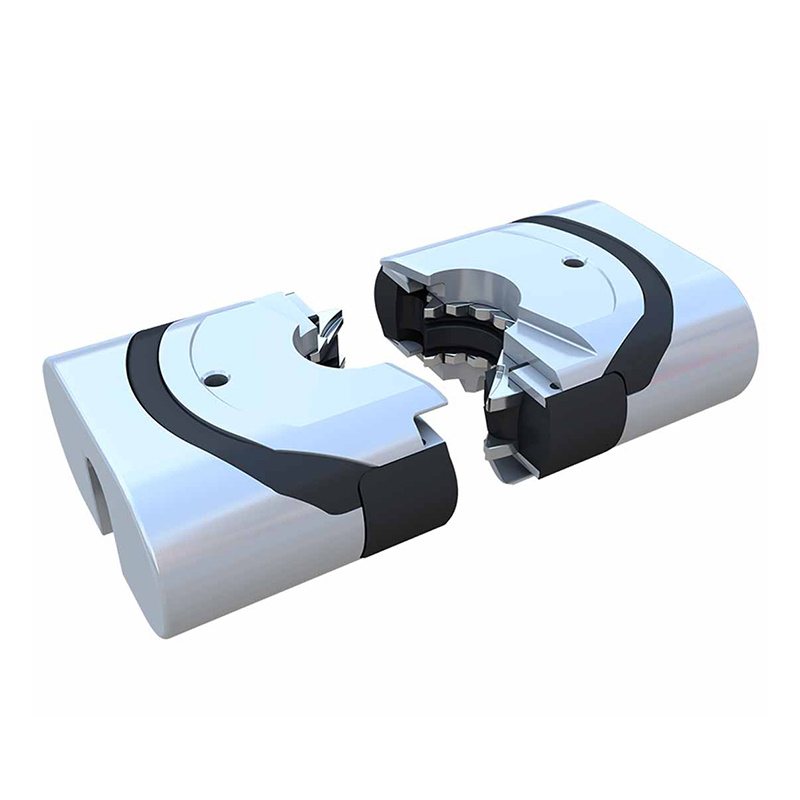

Shear ram is composed of the upper ram body, lower ram body, top seal, right seal, left seal and tool face seal. The tool face seal is placed in the front slot of the upper ram body, with the right seal and left seal on both sides. The shear ram is installed in the BOP in the same manner as the common ram. Type S Shear Ram Assembly is known for its exceptional cutting power and sealing efficiency. Each component plays a critical role in ensuring the ram's functionality - the upper and lower ram bodies providing structural integrity, and the seals ensuring a firm, leak-proof closure post shearing.

The arrangement of the tool face seal in the front slot of the upper ram body, which has the right and left seals, creates an efficient shearing and sealing system. This design allows for effective shearing of the pipe and subsequent sealing of the wellbore, crucial in situations that demand immediate well-control.

Although the installation process mirrors that of common ram assemblies, the type S Shear Ram Assembly requires a specific hanger for the main piston. This specification underlines its distinctive design and capabilities.

Further, the type S Shear Ram Assembly's robust construction allows it to withstand high-pressure environments, enhancing its reliability and lifespan. Its design embodies safety, precision, and performance, making it a vital component in well-control operations.