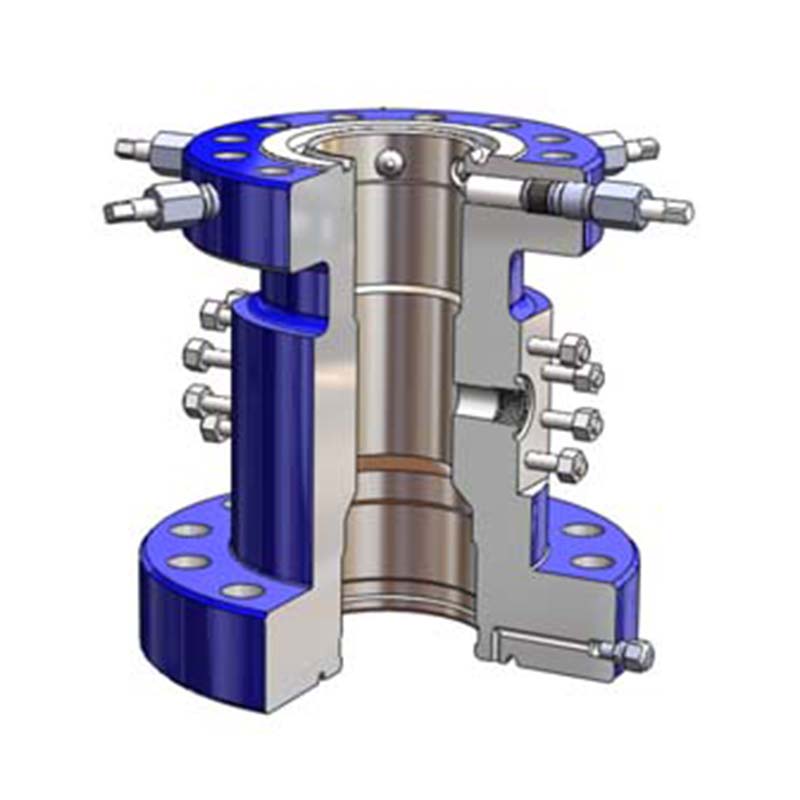

Sucker Rod BOP

Feature

The sucker rod blowout preventers (BOP) is mainly used to seal the sucker rod in the process of lifting or lowering the sucker rod in oil wells, so as to effectively prevent the occurrence of blowout accidents. The Manual Dual Ram Sucker Rod BOP is equipped with one blind ram and one semi-sealed ram each. The upper end of the BOP is equipped with a rod sealing unit. When the sealing rubbers in the rod sealing unit need to be replaced while there is a rod in the well, the semi-sealed ram can seal the rod and annulus to achieve the purpose of well sealing. When there is no sucker rod in the well, the wellhead can be closed with the blind ram.

It is simple in structure, easy to use and maintain, small in size, light in weight, and simple and reliable in operation. It is mainly composed of shell, end cover, piston, screw, ram assembly, handle and other parts.

API 16A 1-1/2 inch (φ38) sucker rod BOP, 1500 - 3000 PSI EUE.

Description

The sucker rod BOP, as a control device to prevent the leakage of oil and gas in the recovery operation, can guarantee the well-flushing, washing, and fracturing downhole operations to proceed smoothly. By changing different valve cores, it can meet the needs of all kinds of rod seals. The product design is reasonable, with a simple structure, convenient operation, reliable sealing, long service life, and is one of the indispensable tools in oil field work.

Main technical parameters:

The maximum working pressure: 10.5 MPa (1500 psi)

Is suitable for sucker rod specifications: 5/8-11/8 (16 to 29 mm) in3,

The upper and bottom nipple: 3 1/2 UP TBG

Specification

|

SIZE(in) |

5/8ʺ |

3/4ʺ |

7/8ʺ |

1ʺ |

1 1/8ʺ |

|

RODD.(IN) |

5/8ʺ |

3/4ʺ |

7/8ʺ |

1ʺ |

1 1/8ʺ |

|

LENGTH(ft) |

2,4,6,8,10,25,30 |

||||

|

OUTSIDE DIAMETER OF PIN SHOULDER(mm) |

31.75 |

38.1 |

41.28 |

50.8 |

57.15 |

|

LINGTH OF PIN(mm) |

31.75 |

36.51 |

41.28 |

47.63 |

53.98 |

|

LENGTH OF WRENCH SQUARE(mm) |

≥31.75 |

≥31.75 |

≥31.75 |

≥3.1 |

≥41.28 |

|

WIDTH OF WRENCH SQUARE(mm) |

22.23 |

25.4 |

25.4 |

33.34 |

38.1 |