Tapered BOP packing element

Description:

The tapered BOP packing element was first developed by Hydril, an American Company and it is used for annular blowout preventers of Hydril type.

The tapered packing element has unique advantages in large diameter and high-pressure working conditions. At present, it is also one of the most widely used blowout-preventer packing elements.

Our OEM tapered packing elements use foreign formulas and technology, which have significant advantages in service life and product reliability.

Our OEM Tapered BOP Packing Elements elevate performance standards by incorporating cutting-edge foreign technologies and formulations. This innovation enhances both product longevity and dependability, providing a superior solution for challenging drilling operations.

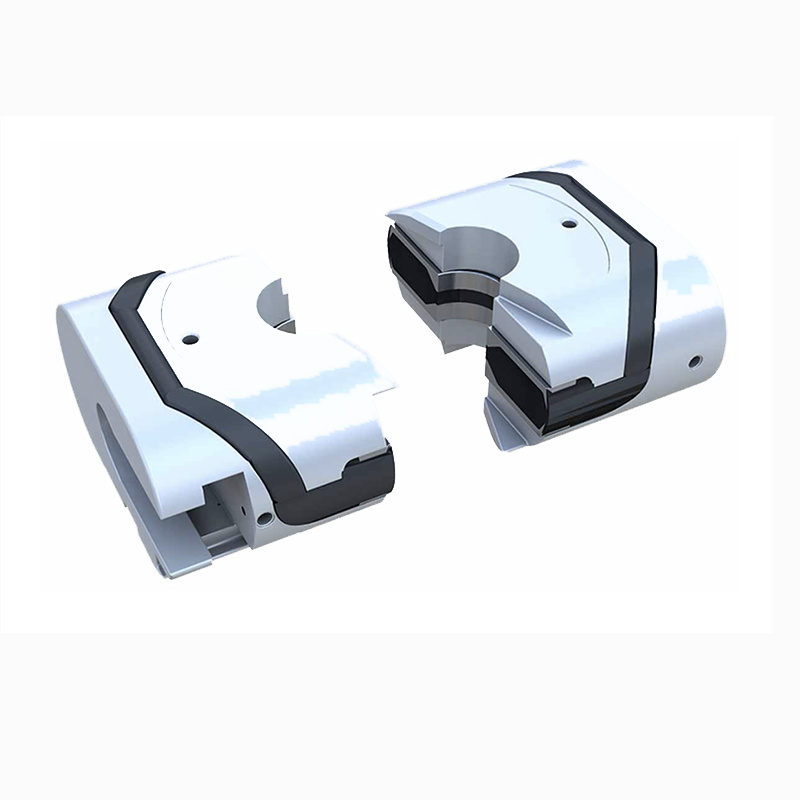

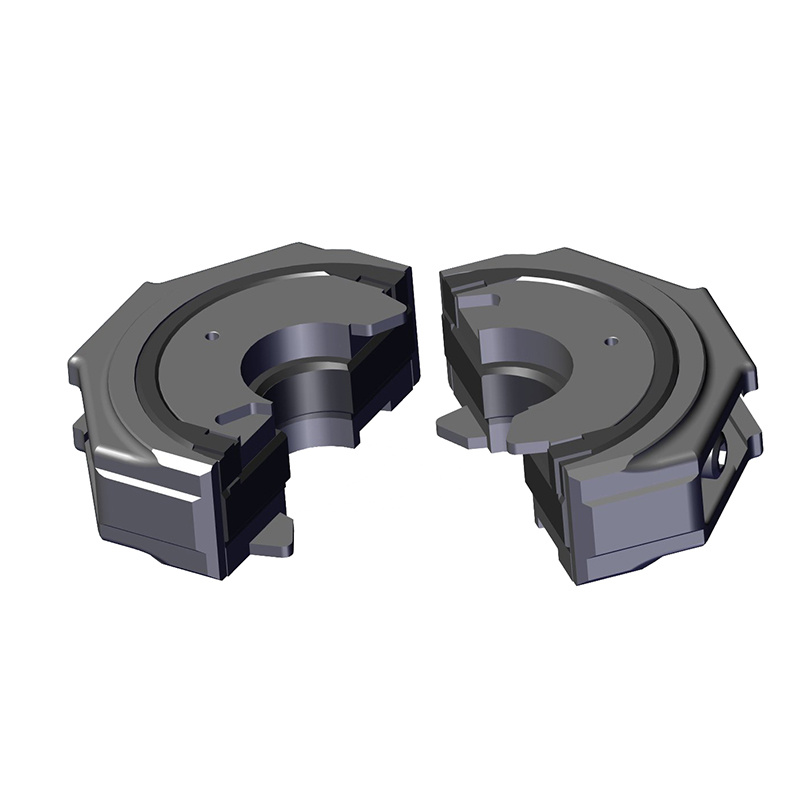

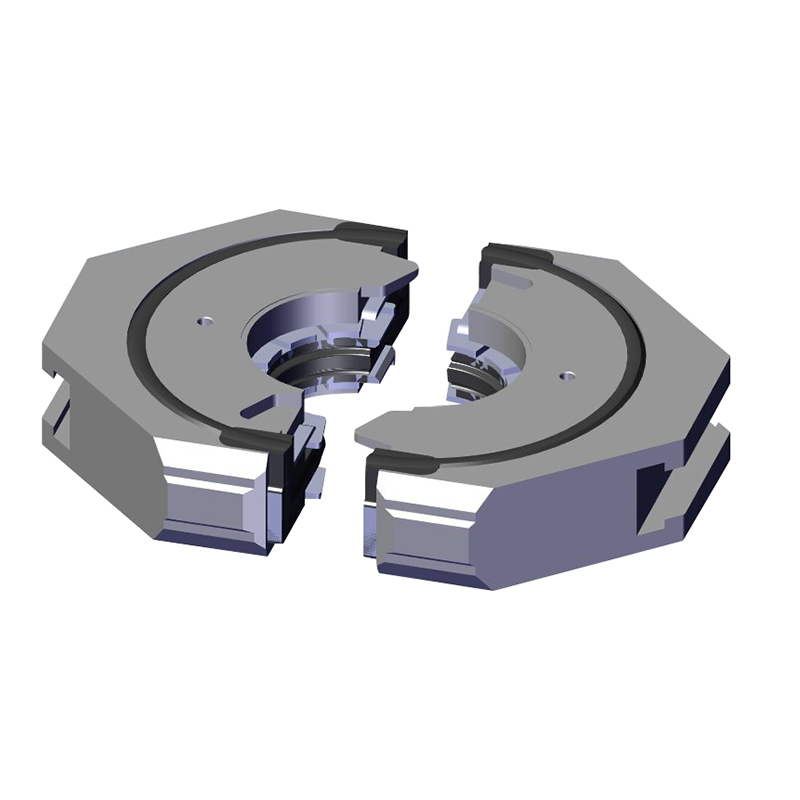

One of the key attributes of the tapered packing element is its unique geometry. The tapering design allows it to handle extreme well pressures, offering a more efficient sealing mechanism. This is particularly useful in large-diameter wellbore situations, where effective sealing can pose significant challenges.

Our OEM version of this element goes a step further in durability. It boasts an advanced material composition that is exceptionally resistant to harsh oilfield conditions. This includes exposure to high temperatures, corrosive drilling fluids, and mechanical stresses.

The element's design also facilitates a straightforward installation process. Its compatibility with numerous blowout preventers enhances its adaptability in diverse drilling environments. This ease of use and versatility contribute to operational efficiency and a reduction in maintenance downtime.

In essence, our OEM Tapered BOP Packing Element symbolizes a significant advancement in well-control equipment. It not only ensures efficient wellbore sealing but also enhances the overall safety and reliability of drilling operations, making it a highly favored choice in the industry.

Specification

| 18 3/4"-10000 PSI /15000 PSI Subsea | 18 3/4"-5000 PSI/10000 PSI Subsea |

| 13 5/8"-10000 PSI/15000 PSI | 21 1/4"-5000 PSI |

| 20 3/4"-3000 PSI | 13 5/8"-5000 PSI |

| 29 1/2"-500 PSI diverter | |