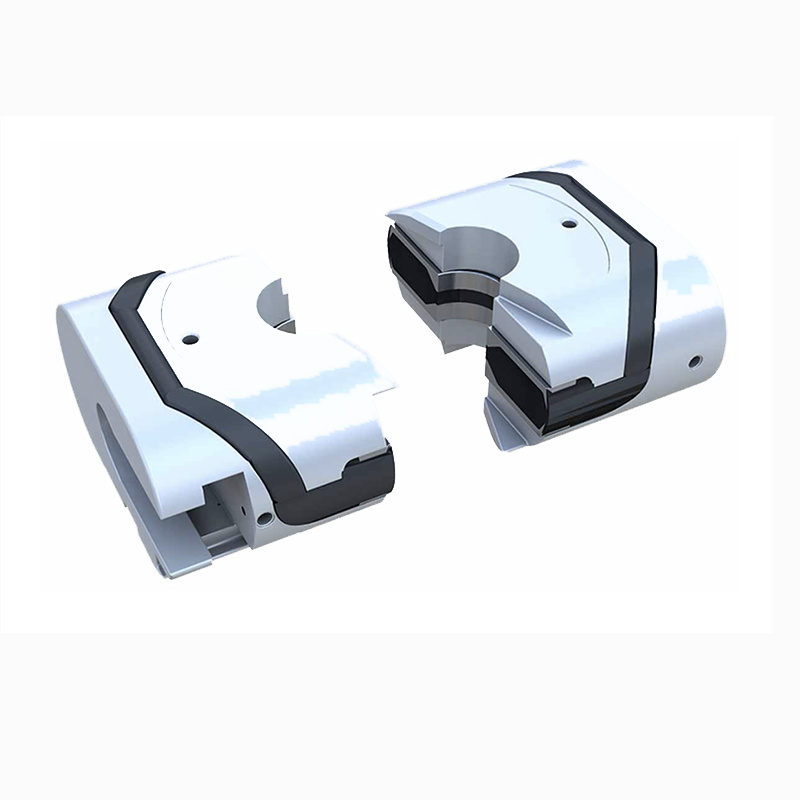

Type U Pipe Ram Assembly

API Spec 16A BOP Rams Main technical parameters

1, Working pressure2000~15000PSI (14~70MPa)

2, Nominal bore7 1/16~13 5/8 (179.4~346.1mm)

3, According to the latest API Spec 16A standard,and quality standard of ISO9001.

Description:

The U Pipe Ram is use for single or double Ram Blowout Preventer(BOP).The ram's size is matched with the pipe's OD. Its can be closed between the pipe stem and well annular space. Type U Pipe Ram provides a robust solution for well control applications in both single and double Ram Blowout Preventer (BOP) setups. Precision engineered to align with the outer diameter of the pipe, the type U Pipe Ram forms a secure seal between the pipe stem and well annular space, ensuring optimum wellbore integrity under varying drilling conditions.

The type U Pipe Ram's design emphasizes ease of use, durability, and a high standard of performance. Made with high-grade materials, it can resist harsh drilling conditions, offering a dependable, long-term solution for effective well control.

A key advantage of this type of pipe ram is its adaptability to different pipe sizes. The flexibility offered by the type U Pipe Ram allows it to be utilized across a wide spectrum of drilling operations, demonstrating its versatility in practice.

Furthermore, the type U Pipe Ram is engineered to minimize fluid leakage, contributing to more efficient and safer operations. Its robust construction and design to form a reliable seal, even under high pressure, make it a critical component of any well control equipment arsenal.