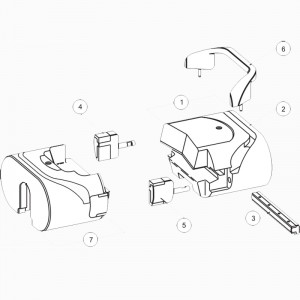

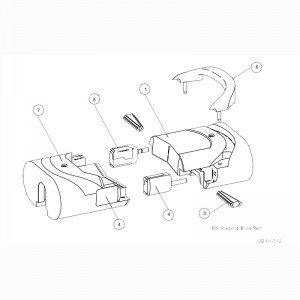

BOP part U type shear ram assembly

Specification

A shear ram can cut pipe in the well, blindly close the wellhead, and also be used as a blind ram when there is no pipe in the well. The installation of the shear ram is the same as the original ram.

● In normal conditions used as a blind ram, in case of emergency, used as a shear ram.

● Shear damper can repeatedly cut pipe and not damage the blade, The wore blade can be reused after the repair.

● The ordinary ram blade is integrated with the ram body.

● The ram blade of BOP resistant to high sulfur is separated from the ram body, which makes it easy to change the blade after blade damage and makes the ram body able to be repeatedly used.

● The contact sealing surface between the top seal of the shear ram and blade is large, which effectively reduces the pressure on the rubber sealing surface, and prolongs its life.

Description:

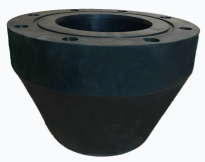

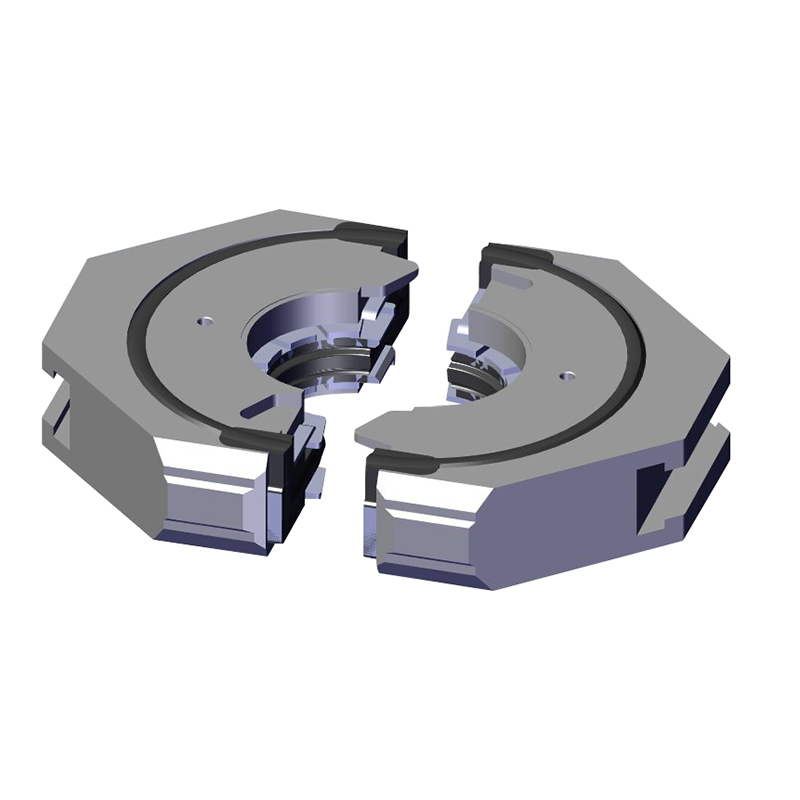

The type U Shear Ram Assembly is a vital piece of well control equipment, designed to effectively manage high-risk drilling situations. The assembly, comprising two key halves - the upper and lower ram bodies - along with an array of highly effective seals, exhibits exemplary cutting and sealing prowess under intense pressures.

The shear ram's foremost responsibility is to quickly sever the drill pipe in the event of a well-control incident, after which it promptly forms a secure seal. This dual-function operation is achieved through the robust construction and strategic design of the assembly.

The top seal, right and left seals, along with the tool face seal, are engineered to provide an impenetrable barrier post-shearing. Together, they help maintain well integrity and provide an essential line of defense against potential blowouts.

Its design facilitates easy installation within the BOP, much like any standard ram. However, a specific hanger is required for the main piston, indicating its unique function within the well-control context. The type U Shear Ram Assembly is a testament to precision engineering, offering unparalleled safety and performance in high-stakes drilling operations.