Wellcontrol Equipment

-

21 1/4”-2000PSI Annular BOP–Seal Kits

PWCE has the complete production line for rubber products, including packing elements and full line of seal kits.

-

21 14″-2,000 Ram BOP (Manual Lock)–Seal Kits

PWCE has the complete production line for rubber products, including packing elements and full line of seal kits.

-

Model D ANNULAR BOP–Seal Kits

PWCE has the complete production line for rubber products, including packing elements and full line of seal kits.

-

7 1/16”- 13 5/8” SL Ram BOP Rubber Packers

• Bore Size: 7 1/16”- 13 5/8”

• Working Pressures: 3000 PSI — 15000 PSI

• Certification: API,ISO9001

• Packing Details: Wooden box

-

Sentry Ram BOP

•Specifications: 13 5/8” (5K) and 13 5/8” (10K)

• Working Pressures: 5000 PSI — 10000 PSI

• Material: Carbon steel AISI 1018-1045 & Alloy steel AISI 4130-4140

• Working Temperature: -59℃~+121℃

• Extreme cold/hot temperature tested to : Blind shear 30/350°F,Fixed bore 30/350°F,Variable 40/250°F

• Execution standard : API 16A,4th Edition PR2 compliant

-

Hydraulic Lock Ram BOP

• Bore Size: 11” ~21 1/4”

• Working Pressures: 5000 PSI — 20000 PSI

• Temperature Range for Metallic Materials: -59℃~+177℃

• Temperature Range for Nonmetallic Sealing Materials: -26℃~+177℃

• Performance Requirement : PR1、PR2

-

Sucker Rod BOP

•Suitable for sucker rod specifications: 5/8″ ~ 1 1/2″

• Working Pressures: 1500 PSI — 5000 PSI

• Material: Carbon steel AISI 1018-1045 & Alloy steel AISI 4130-4140

• Working Temperature: -59℃~+121℃

• Execution Standard: API 6A , NACE MR0175

• Slip & Seal ram MAX hang weights: 32000lb (Specific values by the ram type)

• Slip & Seal ram MAX bears torque: 2000lb/ft (Specific values by the ram type)

-

High Quality Oil Well Drilling Equipment Type S API 16A Spherical BOP

• Application: Onshore drilling rig & Offshore drilling platform

• Bore Sizes: 7 1/16” — 30”

• Working Pressures: 3000 PSI — 10000 PSI

• Body Styles: Annular

• Housing Material: Casting & Forging 4130

• Packing element material: Synthetic rubber

• Third party witness and inspection report available: Bureau Veritas (BV), CCS, ABS, SGS etc.

Manufactured in accordance with: API 16A, Fourth Edition & NACE MR0175.

• API monogrammed and suitable for H2S service as per NACE MR-0175 standard.

-

Taper Type Annular BOP

•Application: onshore drilling rig & offshore drilling platform

•Bore Sizes: 7 1/16” — 21 1/4”

• Working Pressures: 2000 PSI — 10000 PSI

• Body Styles: Annular

• Housing Material: Casting 4130 & F22

• Packer element material: Synthetic rubber

• Third party witness and inspection report available: Bureau Veritas (BV), CCS, ABS, SGS etc.

-

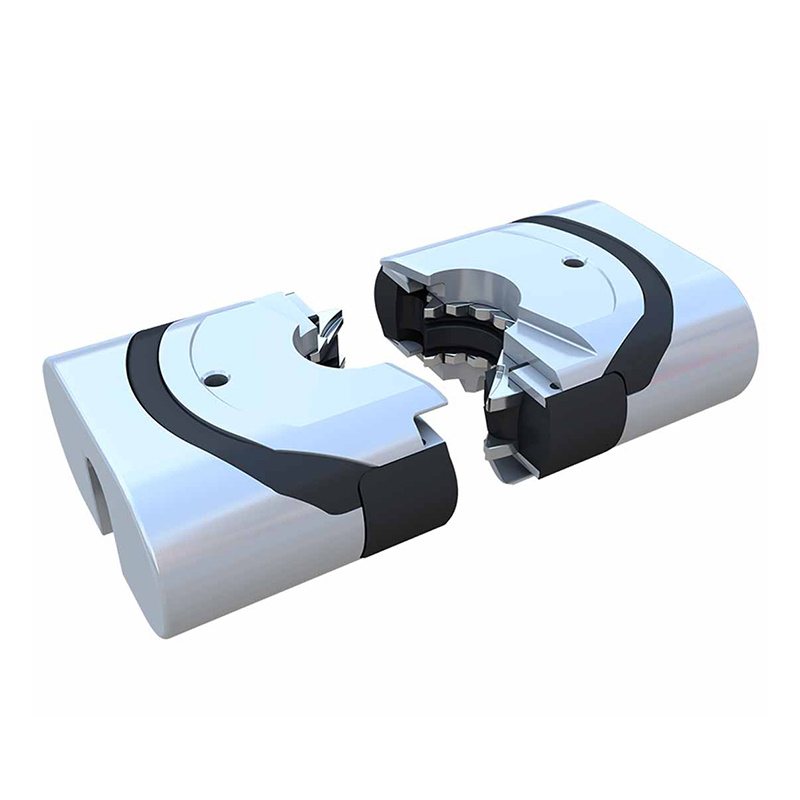

Type U VariabIe Bore Ram Assembly

·Our VBR rams are suitable for H2S service per NACE MR-01-75.

·100% interchangeable with Type U BOP

·Longer service life

·Sealing on a range of diameters

·Self-feeding elastomers

·Large reservoir of packer rubber to ensure a long-lasting seal under all conditions

·Ram packers that lock into place and are not dislodged by well-flow

-

Type U API 16A BOP Double Ram Blowout Preventer

Application: Onshore drilling rig & Offshore drilling platform

Bore Sizes: 7 1/16” — 26 3/4”

Working Pressures: 2000 PSI — 15,000 PSI

Ram style: single ram & double rams

Housing Material: Forging 4130 & F22

Third-party witness and inspection report available: Bureau Veritas (BV), CCS, ABS, SGS, etc.

Manufactured in accordance with: API 16A, Fourth Edition & NACE MR0175.

API monogrammed and suitable for H2S service as per NACE MR-0175 standard

-

“GK”&”GX” Type BOP packing element

-Increase service life by 30% on average

-The storage time of the packing elements can be increased to 5 years, under the shading conditions, the temperature and humidity should be controllable.

-Fully interchangeable with foreign and domestic BOP brands

- Third-party testing can be done during the production process and before leaving the factory according to customer requirements. The third-party inspection company could be BV, SGS, CSS, etc.