Wellcontrol Equipment

-

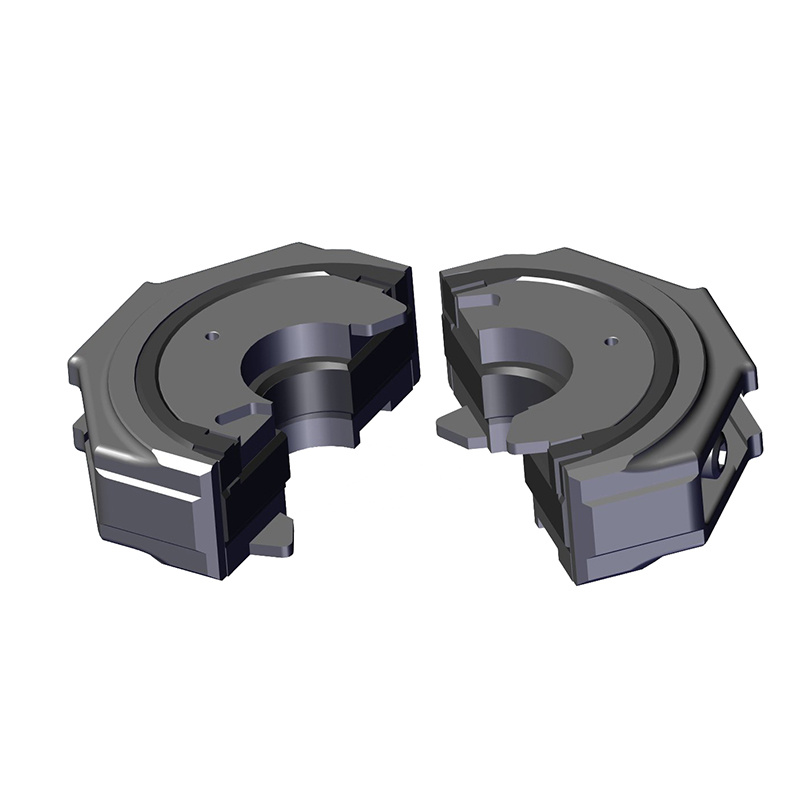

BOP part U type shear ram assembly

The large frontal area on the blade face seal reduces pressure on the rubber and increases service life.

Type U SBRs can cut pipe numerous times without damage to the cutting edge.

The single-piece body incorporates an integrated cutting edge.

H2S SBRs are available for critical service applications and include a blade material of hardened high alloy suitable for H2S service.

The type U shearing blind ram has a single-piece body with an integrated cutting edge.

-

BOP Seal Kits

· Longer service life, Increase service life by 30% on average.

· Longer storage time, the storage time can be increased to 5 years, under the shading conditions, the temperature and humidity should be controllable

· Better high/low-temperature resistant performance and better sulfur-resistant performance.

-

GK GX MSP Type Annular BOP

•Application: onshore drilling rig & offshore drilling platform

•Bore Sizes: 7 1/16” — 21 1/4”

• Working Pressures: 2000 PSI — 10000 PSI

• Body Styles: Annular

• Housing Material: Casting 4130 & F22

• Packer element material: Synthetic rubber

• Third party witness and inspection report available: Bureau Veritas (BV), CCS, ABS, SGS etc.

-

Type T-81 Blowout Preventer For Well Control System

• Application: Onshore drilling rig

• Bore Sizes: 7 1/16” — 9”

• Working Pressure: 3000 PSI — 5000 PSI

• Ram style: single ram, double rams & triple rams

• Housing Material: Forging 4130

• Third-party witness and inspection report available: Bureau Veritas (BV), CCS, ABS, SGS, etc.

Manufactured in accordance with: API 16A, Fourth Edition & NACE MR0175.

• API monogrammed and suitable for H2S service as per NACE MR-0175 standard

-

Blowout Preventer Shaffer Type Lws Double Ram BOP

Application: Onshore

Bore Sizes: 7 1/16” & 11”

Working Pressures: 5000 PSI

Body Styles: Single & Double

Material: Casing 4130

Third party witness and inspection report available: Bureau Veritas (BV), CCS, ABS, SJS etc.

Manufactured in accordance with: API 16A, Fourth Edition & NACE MR0175.

API monogrammed and suitable for H2S service as per NACE MR-0175 standard

-

Diverters for well-control while drilling in the surface layer

Diverters are primarily used for well-control while drilling in the surface layer in the exploration of oil and gas. Diverters are used together with hydraulic control systems, spools and valve gates. The streams (liquid, gas) under control are transmitted to safe zones along a given route to ensure the security of well operators and equipment. It may be used to seal Kelly, drill pipes, drill pipe joints, drill collars and casings of any shape and size, at the same time it can divert or discharge the streams in well.

Diverters offer an advanced level of well control, improving safety measures while boosting drilling efficiency. These versatile devices boast a resilient design that allows for swift and effective responses to unexpected drilling challenges such as overflows or gas influxes.

-

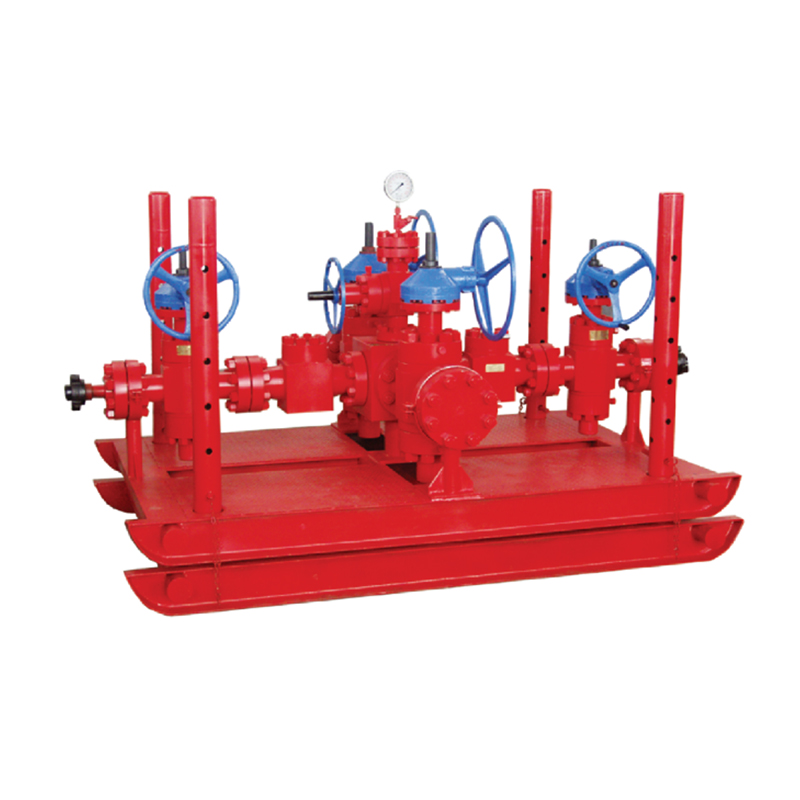

Choke Manifold and kill Manifold

·Control pressure to prevent overflow and blowout.

·Reduce wellhead casing pressure by relief function of the choke valve.

·Full-bore and two-way metal seal

·The internal of the choke is constructed with hard alloy, exhibiting a high level of resistance to erosion and corrosion.

·The relief valve helps to reduce casing pressure and protect BOP.

·Configuration type: single-wing, double-wing, multiple-wing or riser manifold

·Control type: manual, hydraulic, RTU

Kill Manifold

·Kill manifold is mainly used to kill well, prevent fire and assist in fire extinction.

-

Type S Pipe Ram Assembly

The Blind Ram is used for single or double Ram Blowout Preventer(BOP). It can be closed when the well is without the pipeline or blowout.

·Standard: API

·Pressure: 2000~15000PSI

·Size: 7-1/16″ to 21-1/4″

· U type, type S Available

· Shear/ Pipe/Blind/variable Rams