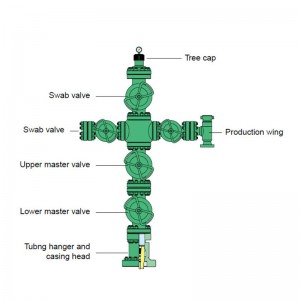

Oil and gas Production Wellhead Equipment

Dual Solid Block Tree

For dual tubing strings, the solid block tree is the most widely used configuration. The two options shown are the most common designs. The valves controlling the flow from the deeper zone, the long string, are the lower valves on the tree. While there are some exceptions to this convention, unless the tree is clearly marked it can be assumed that the valve position reflect the subsurface connections.

The primary components of a wellhead system are

casing head

casing spools

casing hangers

choke manifold

packoffs (isolation) seals

test plugs

mudline suspension systems

tubing heads

tubing hangers

tubing head adapter

Functions

· Provide a means of casing suspension. (Casing is the permanently installed pipe used to line the well hole for pressure containment and collapse prevention during the drilling phase).

· Provides a means of tubing suspension. (Tubing is removable pipe installed in the well through which well fluids pass).

· Provides a means of pressure sealing and isolation between casing at surface when many casing strings are used.

· Provides pressure monitoring and pumping access to annuli between the different casing/tubing strings.

· Provides a means of attaching a blowout preventer during drilling.

· Provides a means of attaching a Christmas tree for production operations.

· Provides a reliable means of well access.

· Provides a means of attaching a well pump.

Specification

API 6A, 20th Edition, October 2010; Specification for Wellhead and Christmas Tree Equipment

ISO 10423:2009 Wellhead and Christmas Tree Equipment

In general well heads are five nominal ratings of wellheads: 2, 3, 5, 10 and 15 (x1000) PSI working pressure. They have an operating temperature range of -50 to +250 degrees Fahrenheit. They are used in conjunction with ring type seal gaskets.

In general the yield strength of the materials range from 36000 to 75000 PSI.